Breaking Wind in Ireland

Part Two

Part Two

Continuing the piece on turbine technology, I am taking a general look at some of Enercon’s innovations in this Post.

Gearless Direct Drive

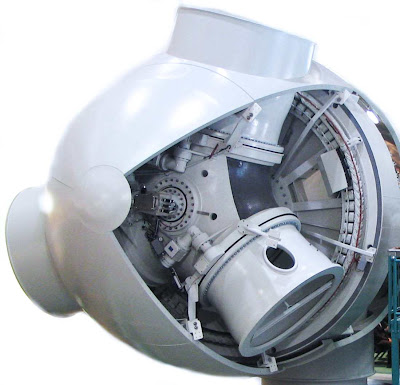

Perhaps Enercon's biggest innovation is the gearless (direct drive) wind turbine which utilises an “annular” or ring shaped generator system. This differs radically from most other wind turbines, which generally use gearboxes in order to increase the rotation speed of the generator.

A drawing to give the general impression of what the annular generator

A drawing to give the general impression of what the annular generatorlooks like. The green bit is the blade hub. The grey bit is the generator.

In wind generators the use of a gearbox increases the noise it makes quite a bit. My impression of sound from turbines was mainly from the gearbox whirr, the swish of the blades was a more organic sound and didn’t register with me. Gearboxes also increase the possibility of breakdowns and decrease the overall efficiency because of friction, the same reason they also need to be fed with oil!

Blades

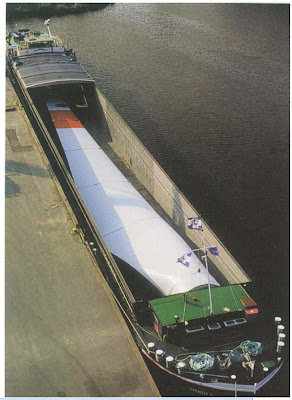

The E126 blades are also a bit of a revolution! (revolution – get it!!) They, unlike current designs, come in two pieces and use the shorter part in steel and the longer part in GRP (Glass Reinforced Plastic – or fibreglass).

The blades have a special profile with extended trailing edge. This design is designed to boost the output.

The Nacelle

Note the huge size of this E112 Nacelle

Note the huge size of this E112 Nacelle it is the size of an average two storey house

if you click on the photo you will get a better image

Blogger has problems sizing photos

Look at the workers to get a perspective of the size!!!

Look at the workers to get a perspective of the size!!!Turbine spotters can easily spot an Enercon turbine as they have a distinctive drop-shaped “nacelle” (the word is derived from the French ‘nacele’ meaning small boat) or generator housing.

Towers

Other Enercon distinctions, for tech spotters, are the towers which are generally painted light green at the base to blend in with their surroundings. Enercon use sectional concrete rather than steel tube towers on their BIG ‘uns.

Other Enercon distinctions, for tech spotters, are the towers which are generally painted light green at the base to blend in with their surroundings. Enercon use sectional concrete rather than steel tube towers on their BIG ‘uns.Shifting the Monsters

As big and all as the E126 is, it can be fairly easily transported. This is due to two main factors. 1. The huge blades coming in two sections, and 2. The precast concrete towers are multi sectional and the bigger diameter lower section are split into two semi-circular pieces. This means the bits can be carried on trucks with a maximum width of only 4.40 meters.

.

No comments:

Post a Comment