A Day on the Farm

Please NOTE

Google Blogger is having a lot of problems recently.

The Photos on this blog may not be visible at times.

Please try again later if that is the case.

Google Blogger is having a lot of problems recently.

The Photos on this blog may not be visible at times.

Please try again later if that is the case.

This is the first of several posts detailing the Nordex N90 and showing some close-ups of the parts and the installation of a blade.

The SWS wind farm at Kilgarvan is a large and impressive site. There are many dirt roads running through the mountain top site, easy enough to get a bit lost up there. The wind-farm is situated on a beautiful mountaintop with absolutely stunning views.

There is about 10 Km of a really rough ride along dirt roads to the very heart of the mountain to where I was to witness the lifting and fitting of a blade to the 80 meter high hub of a Nordex N90 2.5 megawatt turbine.

Met by the Wind Miller

Nordex's site manager Jonathan Millar met me, saw to my safety, and showed me around the installation site. Jonathan has an interesting surname for a new breed of wind mill man. I was allowed to photograph the bits of a wind turbine and I got up close and personal with the massive fibre-glass blades, Jonathan even opened the base plate of one of the blades so I could have a look inside at the construction.

The Nordex N90 Spec. Sheet

The Nordex N90 Spec. Sheet. NOTE: Blogger does not give a clear picture

The Nordex N90 Spec. Sheet. NOTE: Blogger does not give a clear picturePlease click on the picture to get better definition.

Wind turbines like the Nordex N90 with an 80 meter hub height require one heck of a big foundation. In this installation the transformer is set into the base. The large number of tower mounting bolts, which you can see on the above photo, are precision fitted. Just imaging the crane has a huge section of steel tower hanging over the base and there are a couple of bolts an inch out of place??

Not suitable for your Ford Focus

And Gear up from there!

And Gear up from there!A fairly hefty and very high-tech gearbox is used in the Nordex N90. Can you just imagine the kind of torque involved with a rotor having a wingspan of 90 meters, that is 295 feet diameter, spinning in a strong wind? To the right of the gearbox you can see the rotor hub.

The Hub

The Hub

The little house on a pole - aka Nacelle

An Expensive Mobile Home said Jonathan!!

An Expensive Mobile Home said Jonathan!!The Nacelle or box behind the turbine blades houses the gearbox, the control gear and the generator among other bits of hi-tech machinery. I remarked to Jonathan Millar that the fibre-glass nacelle would make a very nice mobile home, a very costly one he retorted.

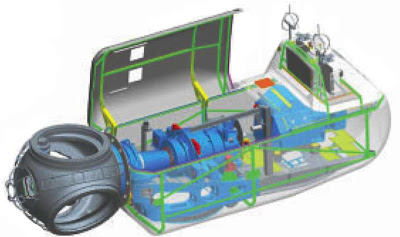

Below are two views of the nacelle, borrowed from the Nordex web site, which gives the layout of the various mechanics and electrics. Further below is a basic listing of the parts.

Below are two views of the nacelle, borrowed from the Nordex web site, which gives the layout of the various mechanics and electrics. Further below is a basic listing of the parts.

1. Pitch Bearing

2. Rotor Hub

3. Pitch Drive

4. Framework

5. Yaw adjustment bearing

6. Main Rotor Shaft

7. Yaw Brakes

8. That Great Big Gearbox!

9. Holding Brake.

10. Coupling to generator.

11. The Heart of the matter - The Generator.

12. Cooler for Generator.

13. Cooler for the Gearbox.

14. Wind Sensors.

15. On-board Crane.

16. The Yaw Drive Mechanism.

17. Support of Gearbox.

18. The Nacelle Fibre-glass Housing

19. Rotor Bearing.

20. Stem of Rotor Blade.

The Fibre-glass Blades

Massive does not adequately describe the huge blades of the N90. They are also elegant and possess a certain beauty of line. The blades are in one piece and are made of fibre-glass and resin, and at the base, have a wall thickness of about 10 cm.

Time for a Walk along a Country Blade!

Time for a Walk along a Country Blade! Above you can see Jonathan walking the length of the blade. To the left you can see the gearbox and hub, while at the blade stem, you can see the nacelle.

Blade Runner?

Blade Runner? Fine living space inside the Blade!

Fine living space inside the Blade!The blades are hollow inside with some just cross bracing pieces to strengthen the structure. There is lightening protection cabling built into the blades.

In fact there are two for rent here!

In fact there are two for rent here! Made from 10cm thick highly compacted fibreglass

Made from 10cm thick highly compacted fibreglass Bit cramped inside the blade! Cross braces spoil a blade run!

Bit cramped inside the blade! Cross braces spoil a blade run!In the next post I aim to show the installation site, the cranes, and the blade being lifted into position.

.

.

No comments:

Post a Comment